BAG

Your bag is currently empty

Sign up and receive 10% off your first purchase.*

By submitting my email, I agree to receive communication from Jo Malone London. See our Privacy Policy. for details.Sign up and receive 10% off your first purchase.*

I agree to receive communication from Jo Malone London. See our Privacy Policy..Need a little inspiration?

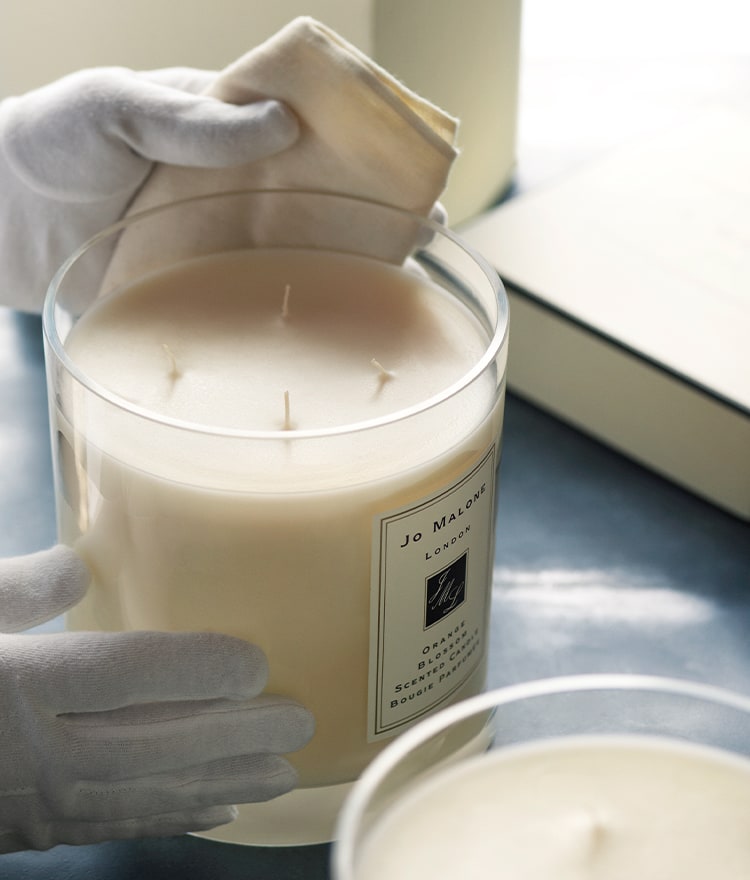

The Craft Of Our Candle

Creating a Jo Malone London candle is a lovingly lengthy affair that requires care and patience. The candle making process takes place in Britain, where we combine cutting-edge technology with a hand-touched approach to ensure that every one is just so. Each candle passes through multiple skilled artisans to guarantee the highest quality.

Our approach to candle making is a masterclass in science and artistry. Our candles are developed with master and technical perfumers, undergoing careful experimentation to ensure they emit that unexpected, timeless scent Jo Malone London is renowned for, delivering exceptional diffusion and quality. Each candle is unique and has undergone the same rigorous fragrance development process as our colognes.

Once the development is all ticked off, it’s time to hit the production line. Fine fragrance oil is blended into slowly warmed wax to create a custom blend that is then decanted, using a process that is never rushed, allowing the candles to slowly cool.

With a smooth, luxurious finish, our wax has been formulated over many years by leading industry experts. We use paraffin wax mixed with an optimal balance of fine fragrance oils to produce a safe, clean and even-burning flame.

Our wax has a few additional benefits: both when unlit and during burning, the wax itself is odourless, allowing a faithful rendition of the fragrance to diffuse and fill the space effectively.

For each new candle the wax composition is altered to suit the fragrance oil and a cotton wick selected from a list of 300. It’s a meticulous process, but crucial to creating the clean, high-performing and aesthetically pleasing candles we’re known for.

Next up is the tricky task of setting the wick. Each wick is held taut by specialist equipment while the soft wax sets, preventing bubbles and ensuring an even burn.

After drying for 72 hours, our candles undergo the last hurrah. They are flashed with an intense heat to ensure the tops are pristine and the wicks are trimmed to a neat 6mm. A label is then applied to the elegantly understated glass holder, which is then polished and buffed by hand. And, for the finishing touch, the placing of the lid complete with a black grosgrain bow.

Browse a selection of candles in different scents and sizes, from Travel Candles to uplift smaller spaces to our showstopping Luxury Candles. You can find the full collection here

Already found the perfect candle for your home? Learn how to care for it and explore our candle care accessories, designed to keep your candles burning brightly.

Shop The Story